Managers and workers are embracing digital technologies, as the fourth industrial revolution reshapes the global economy.

The trend has led to the merging of the internet and factories, giving rise to smart factories and more efficient and cost-effective manufacturing. New data-driven production systems have 20- to 50-percent higher performance, and are transforming the way we transport goods and run supply chains. And, far from creating workplaces in which robots replace humans, new technologies can make work less repetitive, more engaging, and diversified.

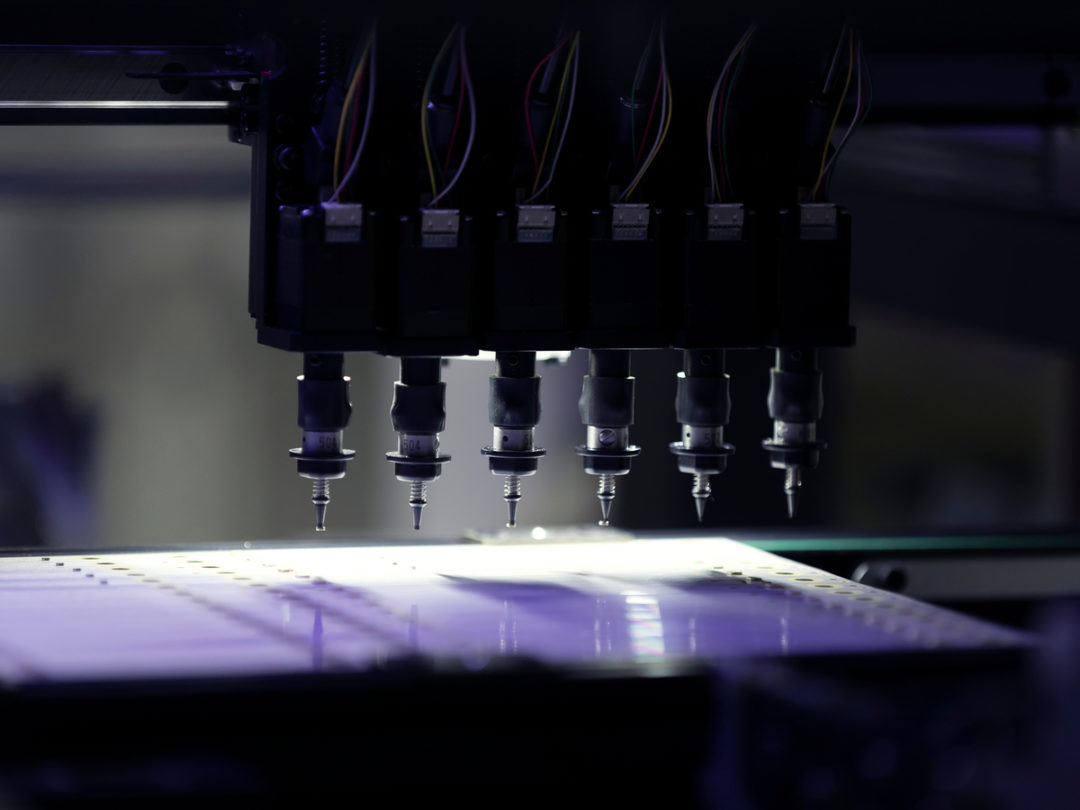

Machines, software, and products in Industry 4.0 factories communicate with one another at each point of the manufacturing process. They produce and exchange data among themselves and with workers through technologies such as sensors, data analytics, the Internet of Things (IoT), cloud computing, robotics, and artificial intelligence (A.I.). This enables smart factories to adapt to customer demands in real time and offer highly personalized products. Furthermore, machines can automatically update themselves through the internet and contact a specialist to troubleshoot them. Smart sensors allow advanced tracking of products and rapid recalls in case of failure. Such a wealth of data enables companies to further optimize their operations, prompting the growth of the smart factory market, which is set to reach $244.8bn by 2024.

The transformation of production processes also means that the era of large inventories is coming to an end. Digital technologies enable companies to create connected supply chains and produce and ship parts only as needed. Robots can pick, sort, and handle orders more efficiently than human workers, while engineers can use predictive analytics to forecast risk and customer behavior. IoT devices such as sensors can feed A.I.-powered software with the data it needs to provide ways to minimize delivery times. And one day, we might even see autonomous trucks on highways delivering products across the world. So it’s no wonder that 70 percent of executives expect digital innovation to significantly impact the future of supply chains.

Procter & Gamble, a multinational consumer goods corporation, has demonstrated just how effective smart factories can be. Its Rakona factory, located in the Czech Republic, produces dishwashing liquids and fabric enhancers. In the period from 2010 to 2016, it underwent significant changes, with management having to increase production capacity for liquid products, cut costs, and attract new business. A number of innovative technologies were been introduced, some more impressive than others.

For instance, a new digital tool was introduced to enable managers to schedule tasks and track their execution. Also, the system now shows live performance metrics of workers, and this has increased the reliability of processes and the effectiveness of machines. Sensors automatically monitor pH value, color, viscosity, and other product details, which makes manual sampling unnecessary, and enables employees to spot quality deviations on time. A new packing system powered by sensors, cameras, scanners, along with a wrapper system, have also been deployed, enabling recipe changes on the packaging even if the line is running.

The Rakona factory especially benefited from web-based, end-to-end supply chain synchronization software, which allows managers to test how different conditions affect the supply chain, spot bottlenecks in manufacturing operations, and deliver products to market faster. As a result of all these measures, the factory reduced inventory by 43 percent and full plant cost by 20 percent. What’s more, it increased productivity by 160 percent and customer satisfaction by 116 percent.

On-time delivery and rapid prototyping are also important elements of smart factories. The U.S. startup Fast Radius, for example, embraced these principles as it placed its 3D printing facility within UPS WorldPort, the world’s largest packaging facility, which handles 300 flights each day. The company provides clients not only with additive manufacturing solutions, but also with more traditional CNC machining and rapid injection-molding capabilities. And thanks to the partnership and financial backing of UPS, a logistics and package delivery company, Fast Radius boasts the industry’s fastest delivery times and can truly pursue just-in-time production. In 2018, it was also included on the World Economic Forum’s list of factories of the future due to, among other things, its innovative business model.

Innovations in manufacturing force companies to rethink the way they manage the transport of products, too. To that end, plans by the likes of Uber and Tesla to develop self-driving semi-trucks are a sign of things to come, and those vehicles might one day autonomously deliver goods and charge clients. Technology is also tackling the inefficiencies of global supply chains, as smart factories require fast transport of goods. To that end, IBM and shipping giant Maersk have developed TradeLens, a blockchain-based platform that brings shippers, ports, banks, and customs offices into a single network. The aim is to enable these actors to record information in tamper-resistant digital records and track, tax, and move goods faster than paperwork-based supply chains.

The benefits of smart factories are evident, but deploying cutting-edge solutions to the factory floor is a challenging task. Over 70 percent of businesses that invest in technologies such big data, A.I., or 3D printing fail to take the project beyond the pilot phase. One of the reasons for such an abysmal track record is that not only do current employees need upskilling, but the company also must hire a number of software and engineering experts that are often hard to find.

Also, there’s a limit to just how many tech solutions a company should deploy. Frank Piller, an Industry 4.0 expert, warns companies not to “turn [their] workforce into cyborgs or let the technology guide the worker, but provide [their] workforce with a toolbox to make their own work more efficient and fun, too.” And as we move forward, it will be increasingly important that entrepreneurs share their experiences on how to build effective, tech-driven factories and avoid common pitfalls.

Future factories are more than just a rethink of the production process. They’re a radical shift in the way many manufacturing and supply-chain companies build their business models. Smart factories minimize waste, maximize profit, and make customers happy. Their operations are built around digital technologies that make work more interesting and fun, and lead to new opportunities.

Adapting to change isn’t easy, however. For manufacturers, it means implementing new business models and abandoning old practices. But the reward for the pioneers of the Fourth Industrial Revolution is impressive, as they’ll future-proof their companies and ensure growth for many years to come.

Richard van Hooijdonk is an international keynote speaker, trend watcher and futurist.