For the average consumer, supply disruptions caused by the COVID-19 pandemic over the past three years were a matter of mere inconvenience. That wasn’t the case with medical device manufacturers, for whom the stakes were dramatically higher.

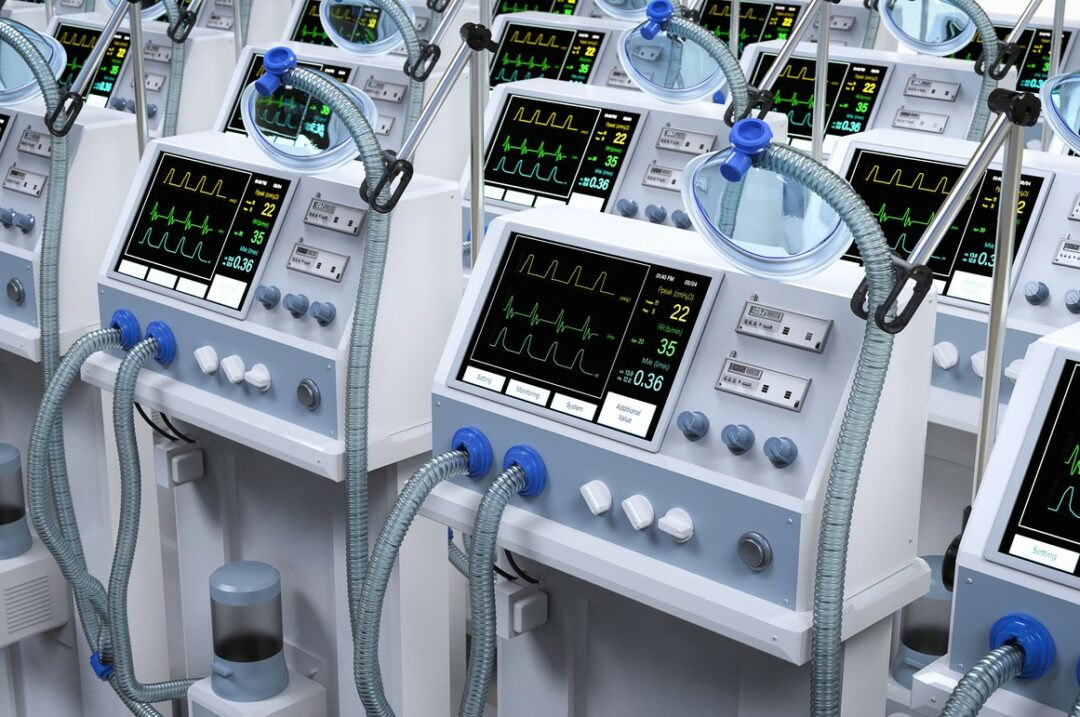

The medical device category covers everything from 10-cent bandages to seven-figure MRI machines. At the lower-price end, doctors and nurses were forced to wear the same masks for five days straight, duct taping them after they tore. When it came to more expensive life-saving equipment, ventilators were in short supply, and healthcare providers considered retooling old CPAP (continuous positive airway pressure) machines.

Even with the fading of COVID-19 in the U.S., some supply problems have persisted. In the pharmaceutical space, there have been shortages of baby formula, and Children’s Tylenol disappeared from shelves as RSV (respiratory syncytial virus) raged. And at the higher end, production of GE Healthcare CT Scan machines slowed in May, 2022 when medical dye became delayed due to the shutdown at a plant in Shanghai. Mass General, a leading hospital, was forced to send out a memo advising physicians to conserve some supplies.

Not surprisingly, supply chain resilience has become top of mind for medical professionals and device manufacturers. To alleviate some of these pain points, companies should consider the following common-sense strategies for building greater supply chain resilience.

Understand your exposure. Businesses can expect to see more supply chain disruptions in the foreseeable future, while being exposed to greater public scrutiny. Now is the time to protect against these heightened risks to solidify your supply chain and strengthen your resiliency plans.

Focus on the small. Among the many lessons of COVID-19 is the understanding that small things matter. A virus caused 6.8 million deaths globally and brought planet Earth to a halt. N95 masks became the most important element in providing care. Toilet paper was hoarded, and the short supply of contrast froze million-dollar machines. Small products and parts rely on supply chains supported by parcel carriers such as USPS, UPS, and FedEx, and often face more competition for their purchases. The third-party supplier of your CT scan machine core might be committed to getting you product, while the manufacturer of a plastic resin or cotton that goes into the gauze for your bandages might have other channels to which it can sell to more profitably. Remember that the smallest part in a medical-device array can cause an outage, and keep patients from receiving the care they need.

Realize that service matters. Top medical-device companies realized decades ago that service matters, accounting in some instances for more than a third of revenues. Any delay in servicing critical machines results in broken commitments to customers and their patients.

Re-evaluate your contracts. Organizations should know which contractual clauses present the most risk. It’s vital to understand the commitments (or lack thereof) contained in customer contracts, and how they can affect your ability to deliver. Ask the following questions:

- What am I contracted to deliver to my customers?

- How fast must I deliver equipment, consumables or service?

- What are the remedies if I fail to perform?

- Which force majeure and acts of God conditions protect against penalties for non-performance?

- Can I invoke price escalations on my customers? Are they based on the CPI or other metrics? Can my suppliers do the same to me?

Perform the same tests on your supplier contracts. Do you have supplier agreements established with secondary and tertiary suppliers for even the smallest parts? What about your labor force? Understand that failures in supplier contracts can cause failures in your sales and service contracts as well. If you don’t already have a contract repository, now is the time to streamline contract-management processes. That daunting project has gotten easier with artificial intelligence tools, which can read your legacy contracts and identify key clauses and meta data. Invest the time in establishing new contracts and clauses and amending existing ones.

COVID-19 made the world a scarier and more complicated place. Evaluate the complexities in your supply chains, the depth of your customer and supplier relationships, and the contracts that enable and protect your organization. Go a step further and apply these common-sense strategies for focusing on delivering patient care, while improving compliance and reducing business risk.

Tom Cowen is head of vertical strategy, healthcare and life sciences at Conga.