As the supply chain continued to recover from logjams caused by the COVID-19 pandemic, good news came in March with release of the latest Logistic Managers’ Index, which now sits at an all-time low. Transportation prices continue to fall, inventory levels are growing, and warehouse and transportation capacity is seeing growth at increasing rates.

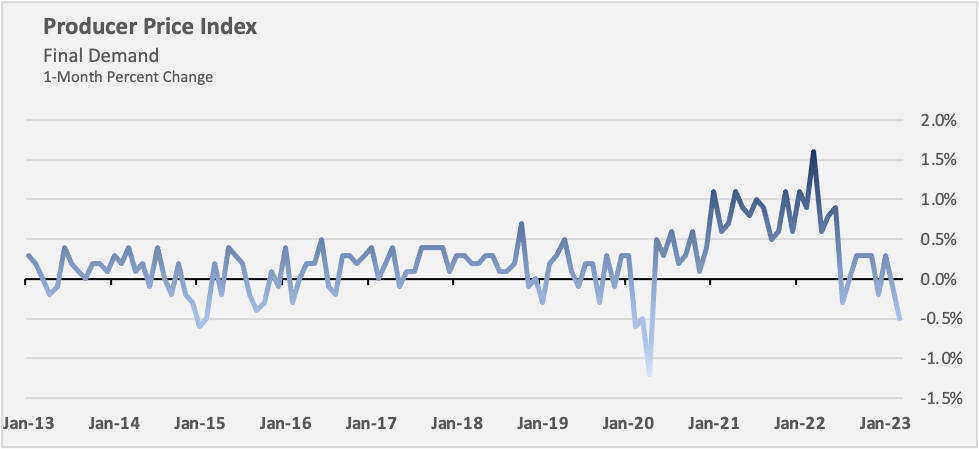

The Producer Price Index (PPI), the main measure of selling price inflation for domestic producers, is also easing. The March numbers showed month-to-month prices decreasing, and this could indicate a future where companies face downward cost pressures.

PPI for final demand, 1-month percent change, seasonally adjusted, Bureau of Labor Statistics

Taken together, these metrics show that supply chain professionals will once again play a crucial role in protecting their company’s profitability. Many industries became used to inflation through the pandemic and raised prices accordingly. Price/cost mix drove healthy gross margins for many, but are we now seeing the need to lower prices? Will inflation translate to lower margins?

Regardless of what happens, preparation is key. Following are six actions that companies can take, as they transition to a flat or declining inflationary environment.

Demand cost relief from your suppliers. Football coach Bear Bryant was fond of saying, “Defense wins championships.” In business, this means protecting margins by proactively pursuing cost decreases. As supply chains open up and inflation moderates, find a target-rich environment for lowering cost.

Employ the “Rocket and Feather” model. During the pandemic, companies built the reflex to quickly raise prices to protect margins. As you pursue cost decreases from your suppliers, consider delaying the equivalent lowering of price. By being proactive with cost reductions and standing firm on price, you’ll pocket additional margin while the competition plays catch-up. If and when you do lower prices, you will already have an improved cost position to support “new normal” margins.

Understand your competitors’ positioning. If you do find that competitors are lowering prices, do your homework to verify what’s being changed. Are specific SKUs being targeted, or are the changes across the board? How big are the changes? If they’re targeted or the decrease is small, then perhaps you don’t need to respond. However, if the reduction demands a response, then make an informed decision instead of reacting rashly.

Differentiate your business. Position a price decrease in a way that can’t be easily copied. For example, lower prices can be driven by expanded inventory, investment in logistics or greater efficiency, rather than a simple “cost down, price down” story. That way, you avoid setting the stage for a downward spiral if costs continue to fall, and competition won’t feel forced to match you.

Engage in a tactical retreat. Select a handful of bellwether products, reduce the price, and inform customers that you’re working hard to deliver great products at an improved price. The marketing halo provided by the decrease should more than make up for the revenue and margin lost from the lower prices of non-core SKUs. It may also prevent customers from looking elsewhere if they know you’ll continue to deliver fair prices.

Don’t compete on price. Finally, attempt to compete on anything other than price. What other value can you bring to the table? Can you offer faster shipping, a competitive bundle, or a new service that will further differentiate you from the competition and take the emphasis off price?

In the end, markets change quickly and businesses need to react. As supply chains slacken and inflation calms, arm yourself with the latest data so you can plan proactively, or risk being taken by surprise.

Dan Cakora is a business consultant with Vendavo.