Visit Our Sponsors |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The supply squeeze on the U.S. economy tightened further in February, indicating scant relief for domestic producers and pointing to persistent inflationary pressures.

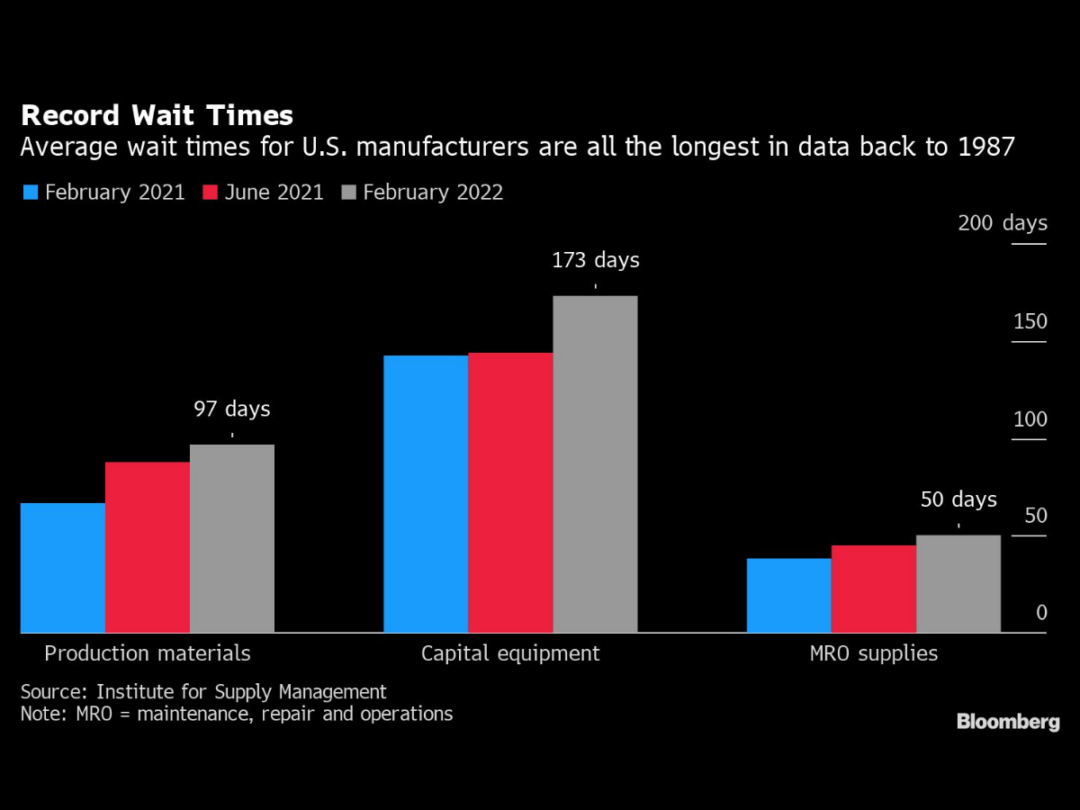

The Institute for Supply Management’s latest survey of purchasing managers showed the average lead times for production materials, capital equipment and supplies all reached the highest records back to 1987, according to a report Tuesday.

What took 67 days a year ago, the average wait time for materials used in the manufacturing process is now a whopping 97 days. Wait times for capital equipment are also a month longer than they were in February 2021, the data showed.

“Improving supply chains are key to slowing inflation through this year, but businesses are still complaining about not being able to fully meet demand,” Will Compernolle, senior economist at FHN Financial, said in a note.

The pickup in lead times is worrisome for economists betting that supply chains will get back in order this year and alleviate decades-high inflation. Demand is still high, so the delays risk keeping prices elevated for that much longer.

The ISM’s measure of order backlogs jumped by 8.6 points in February, the largest monthly advance in 11 years. The purchasing managers group’s overall index of manufacturing activity climbed last month as new orders growth strengthened.

Persistent shipping challenges, pandemic-related production interruptions in export-driven economies like China, transportation delays and labor-supply constraints in the U.S. remain hurdles for faster production growth at domestic manufacturers.

One computer and electronic products industry purchasing manager said the “electronic supply chain is still a mess,” the ISM survey showed. Another purchaser in the textiles industry said they are “expecting a year of strong demand, higher prices and continued supply chain challenges.”

RELATED CONTENT

RELATED VIDEOS

Timely, incisive articles delivered directly to your inbox.